High-Quality Custom Brass Sheet Cutting Services

By:Admin

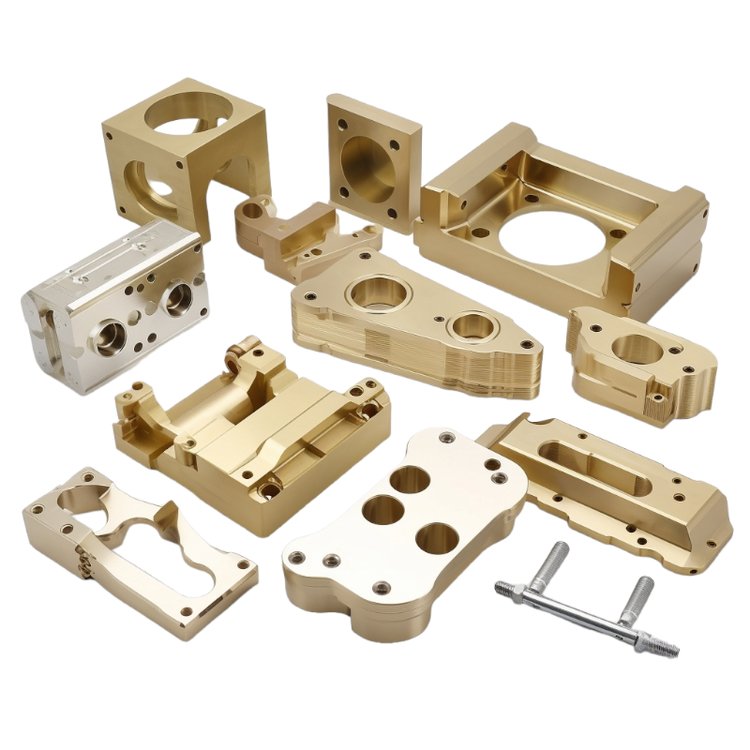

When it comes to manufacturing and construction, the demand for high-quality metal products is ever-present. This is where Custom Cut Brass Sheet comes into play, offering a versatile and durable solution for a wide range of applications. With its expertise in metal fabrication and commitment to quality, {company name} is proud to provide custom-cut brass sheets that meet the unique needs of its customers.

{Company name} is a leading provider of metal fabrication services, specializing in the cutting and shaping of various metals to meet the specific requirements of its clients. With state-of-the-art equipment and a team of skilled professionals, the company has built a reputation for delivering precision-cut metal products that exceed industry standards.

Brass is a popular choice in many industries due to its excellent corrosion resistance, malleability, and attractive golden appearance. It is commonly used in electrical components, plumbing fixtures, architectural applications, and decorative elements. Custom Cut Brass Sheet from {company name} is available in a variety of thicknesses, widths, and lengths, allowing for precise customization to fit the needs of each project.

One of the key advantages of brass is its versatility, making it suitable for a wide range of applications. Whether it's for architectural accents, industrial equipment, or musical instruments, brass sheets have the strength and durability to withstand diverse environments and conditions. The skilled team at {company name} understands the unique properties of brass and is committed to delivering custom-cut sheets that meet the exact specifications of each project.

In addition to its durability, brass is also known for its excellent conductivity, making it an ideal material for electrical applications. Custom Cut Brass Sheet from {company name} is widely used in the manufacturing of switches, connectors, and terminals, where reliable electrical conductivity is essential. With precise cutting and shaping capabilities, the company ensures that its brass sheets are ready for immediate use in electrical components and systems.

{Company name} is dedicated to meeting the needs of its customers, offering custom-cut brass sheets that are tailored to their specific requirements. Whether it's for a large-scale construction project or a small-scale manufacturing operation, the company's expertise in metal fabrication allows for the production of brass sheets in various sizes and thicknesses, ensuring that each client receives a product that perfectly suits their needs.

With a commitment to quality and customer satisfaction, {company name} takes pride in its ability to deliver custom-cut brass sheets that meet industry standards and exceed the expectations of its clients. The company's state-of-the-art facilities and cutting-edge technology enable it to produce high-quality brass sheets with precision and accuracy, ensuring that every order is completed to the highest standards of craftsmanship.

In conclusion, Custom Cut Brass Sheet from {company name} offers a reliable and versatile solution for a wide range of applications in various industries. With its expertise in metal fabrication and commitment to quality, the company continues to be a trusted provider of custom-cut brass sheets that meet the unique needs of its customers. Whether it's for architectural, industrial, or electrical applications, {company name} is dedicated to delivering high-quality brass sheets that exceed industry standards and provide long-lasting performance.

Company News & Blog

Metal cutting CNC machine: The latest technology for precise and efficient metal fabrication

The manufacturing industry has been revolutionized by the introduction of computer numerical control (CNC) machines, which have vastly improved precision and efficiency in metal cutting processes. One company at the forefront of this innovation is {}, a leading provider of CNC machines and metal cutting solutions.{} has made significant contributions to the industry through its cutting-edge technology and commitment to quality. The company's CNC machines are known for their high-performance capabilities and ability to meet the diverse needs of its customers. With a strong focus on research and development, {} continuously strives to improve its products and stay ahead of the competition.The latest offering from {} is its advanced CNC machine for metal cutting, which is designed to deliver superior accuracy and speed. This cutting-edge machine utilizes state-of-the-art technology to ensure precise and efficient cutting of various types of metal, including steel, aluminum, and titanium. With its user-friendly interface and programmable features, the CNC machine offers unparalleled control and flexibility in the manufacturing process.Furthermore, {} has incorporated advanced robotics and automation into its CNC machines, allowing for seamless integration and optimized production workflows. This results in increased productivity and reduced lead times, ultimately providing cost savings for its customers. The company's commitment to sustainability is also evident in its energy-efficient manufacturing processes, which contribute to a greener and more environmentally friendly industry.In addition to its innovative technology, {} takes pride in its dedication to customer satisfaction and support. The company offers comprehensive training programs and technical assistance to ensure that its customers can maximize the full potential of their CNC machines. With a team of skilled engineers and technicians, {} provides prompt and reliable service, ensuring minimal downtime and optimal performance of its machines.With its relentless pursuit of excellence, {} has established itself as a trusted and reputable provider of CNC machines for metal cutting. Its commitment to quality, innovation, and customer satisfaction continues to set the company apart in the competitive manufacturing landscape. As the industry evolves, {} remains at the forefront, continually pushing the boundaries of what is possible in metal cutting technology.Manufacturers looking to enhance their production capabilities can confidently turn to {} for cutting-edge CNC machines that deliver precision, efficiency, and reliability. With a proven track record of success and a dedication to driving innovation, {} is poised to remain a leader in the industry for years to come.

Innovative 5 Axis Parts for Precision Manufacturing Now Available

5 Axis Parts, a leading manufacturer in precision machining, has continued to innovate and expand its capabilities in the field of advanced manufacturing. With a strong focus on delivering high-quality, complex components for a wide range of industries, the company has established itself as a trusted partner for businesses looking for reliable and efficient manufacturing solutions.Specializing in 5-axis CNC machining, 5 Axis Parts has the ability to produce intricate and precise parts with unparalleled accuracy and efficiency. The company's state-of-the-art facilities and advanced technology allow for the production of complex geometries and tight tolerances, making it a preferred choice for customers with demanding machining requirements.In addition to its expertise in 5-axis machining, 5 Axis Parts also offers a wide range of other manufacturing capabilities, including CNC turning, milling, and Swiss machining. This comprehensive suite of services enables the company to meet the diverse needs of its customers, providing them with a one-stop solution for all their machining needs.One of the key differentiators of 5 Axis Parts is its commitment to continuous improvement and investment in the latest manufacturing technologies. The company regularly upgrades its equipment and processes to stay at the forefront of industry advancements, ensuring that customers receive the highest quality parts with the fastest lead times.Furthermore, 5 Axis Parts is dedicated to maintaining the highest standards of quality and precision in all aspects of its operations. The company is ISO 9001 certified, and its stringent quality control measures guarantee that every part produced meets the strictest specifications and requirements.With a team of highly skilled engineers, machinists, and quality control experts, 5 Axis Parts is capable of handling the most challenging and complex machining projects. The company works closely with its customers to understand their unique needs and provide tailored solutions that exceed expectations.5 Axis Parts serves a wide range of industries, including aerospace, defense, automotive, medical, and electronics. Its ability to work with a variety of materials, such as aluminum, steel, titanium, and exotic alloys, makes it a versatile partner for businesses across different sectors.Recently, 5 Axis Parts announced the addition of a new 5-axis CNC machining center to its production capabilities. This cutting-edge machine features advanced technology and precision control, further enhancing the company's ability to manufacture complex parts with speed and accuracy.The new machining center is equipped with high-speed spindles, tool changers, and multi-axis capabilities, enabling 5 Axis Parts to take on even more challenging projects and deliver superior results to its customers. The addition of this state-of-the-art equipment is a testament to the company's ongoing commitment to innovation and excellence in advanced manufacturing."We are thrilled to announce the expansion of our capabilities with the addition of our new 5-axis CNC machining center," said the spokesperson of 5 Axis Parts. "This investment demonstrates our dedication to providing our customers with the best possible manufacturing solutions and reaffirms our position as a leader in precision machining."As 5 Axis Parts continues to grow and expand its capabilities, it remains focused on delivering exceptional quality, precision, and service to its customers. With its proven track record of excellence and a relentless pursuit of continuous improvement, the company is well-positioned to meet the evolving needs of the manufacturing industry and exceed the expectations of its customers.

Discover the Benefits of Anodized Aluminum in Various Industries

Anodized Aluminum is a versatile and durable material that is used in a wide range of industries, from aerospace and automotive to consumer electronics and architecture. The anodizing process creates a protective oxide layer on the surface of the aluminum, making it resistant to corrosion and wear. {} is a leading manufacturer of anodized aluminum products, providing high-quality solutions for various applications.Founded in 1990, {} has established itself as a reliable and innovative supplier of anodized aluminum products. With a focus on quality, precision, and customer satisfaction, the company has grown to become a trusted partner for businesses across the world. {} is committed to continuous improvement and investment in advanced technology, ensuring that their products meet the highest standards of performance and reliability.The company's anodized aluminum products are used in a wide range of industries, including aerospace, automotive, consumer electronics, and architecture. Their expertise in anodizing technology allows them to offer customized solutions that meet the specific needs of their customers. Whether it's a highly durable coating for aircraft components or a decorative finish for consumer electronics, {} has the capabilities to deliver top-quality results.One of the key advantages of {}'s anodized aluminum products is their resilience and longevity. The anodized surface provides excellent resistance to corrosion, abrasion, and wear, making it an ideal choice for demanding applications. This durability ensures that the products can withstand harsh environmental conditions and maintain their appearance and performance over time.In addition to its physical properties, anodized aluminum also offers a wide range of color options, allowing for versatile and customized designs. {} offers a variety of color finishes, including natural metallic shades, vibrant colors, and even custom color matching. This flexibility in aesthetics makes anodized aluminum a popular choice for architectural elements, consumer products, and other design-driven applications.Furthermore, {}'s commitment to sustainability is reflected in its anodizing process. The company has implemented environmentally friendly practices and technologies to minimize its impact on the environment. This includes the use of recycled aluminum, energy-efficient processes, and waste reduction measures. As a result, customers can be assured that they are choosing anodized aluminum products that are produced with a focus on sustainability and responsible manufacturing.With a strong emphasis on research and development, {} continues to push the boundaries of anodized aluminum technology. The company invests in advanced equipment, materials, and processes to stay at the forefront of the industry. This dedication to innovation has enabled {} to develop new products and solutions that meet the evolving needs of their customers and the market.In conclusion, {} is a leading manufacturer of anodized aluminum products, offering high-quality, durable, and customizable solutions for a wide range of industries. With a focus on quality, innovation, and sustainability, the company has established itself as a trusted partner for businesses worldwide. Through its commitment to excellence and continuous improvement, {} continues to set the standard for anodized aluminum products and technologies.

High-Quality Brass Fabrication Services for Custom Projects

Custom Metal Fabrication Company Excels in Brass FabricationWith a focus on precision, quality, and efficiency, Custom Metal Fabrication Company has established itself as a leader in the industry. Specializing in a wide range of metal fabrication services, the company has a proven track record of delivering exceptional products to its customers. Among its many specialties, brass fabrication stands out as one of the company's top offerings.Brass fabrication requires a high level of expertise and attention to detail, as brass is a unique metal that demands a skilled hand to work with. Custom Metal Fabrication Company has honed its brass fabrication techniques over the years, developing a reputation for excellence in this specialized field. From custom brass parts to intricate brass components, the company has the knowledge and capabilities to exceed its customers' expectations."We take great pride in our brass fabrication capabilities," says [Name], CEO of Custom Metal Fabrication Company. "Brass is a beautiful and versatile material, and we have mastered the art of working with it to create outstanding products for our clients."The company's brass fabrication process begins with a careful assessment of the customer's needs and specifications. From there, its team of skilled engineers and fabricators work closely with the client to develop a custom solution that meets their exact requirements. Using state-of-the-art equipment and cutting-edge techniques, the company is able to produce precision-crafted brass components with unmatched accuracy.Custom Metal Fabrication Company's dedication to quality is evident in every step of its brass fabrication process. From the initial design phase to the final inspection, the company's team is committed to upholding the highest standards of craftsmanship. This attention to detail ensures that each brass piece that leaves the facility is of the utmost quality, meeting or exceeding the customer's expectations.In addition to its technical expertise, Custom Metal Fabrication Company is also known for its exceptional customer service. The company believes in building strong, collaborative relationships with its clients, working closely with them throughout the fabrication process to ensure their complete satisfaction. This customer-centric approach has earned the company a loyal customer base and a reputation for reliability and integrity."Our customers are at the heart of everything we do," [Name] explains. "We go above and beyond to deliver the best possible service and products to them. Our goal is to not just meet, but exceed their expectations in every aspect."With its combination of technical prowess, superior craftsmanship, and unwavering commitment to customer satisfaction, Custom Metal Fabrication Company has solidified its position as a top provider of brass fabrication services. Whether the project calls for intricate brass components or larger-scale brass structures, the company has the expertise and capabilities to deliver outstanding results.Looking ahead, Custom Metal Fabrication Company is poised to continue its success in the brass fabrication market. The company remains dedicated to staying at the forefront of industry trends and advancements, ensuring that it can consistently provide its clients with the best possible solutions. As the demand for high-quality brass fabrication services continues to grow, Custom Metal Fabrication Company is well-positioned to meet and exceed the expectations of its customers.In conclusion, Custom Metal Fabrication Company's expertise in brass fabrication sets it apart as a leader in the industry. With its unwavering commitment to quality, precision, and customer satisfaction, the company has earned a well-deserved reputation for excellence. As it continues to expand its capabilities and services, Custom Metal Fabrication Company is poised to remain a top choice for brass fabrication needs.

Online Ordering for CNC Products: A Complete Guide

CNC Online Order Enhances Customer Ordering Experience (Remove Brand Name)In today’s fast-paced and highly competitive business world, companies are constantly looking for innovative ways to improve their operations and enhance the overall customer experience. With the rise of e-commerce and online ordering, many companies are turning to digital platforms to streamline their ordering processes and provide customers with a more convenient and efficient way to purchase their products and services.One company that is leading the way in this digital transformation is {}. With over [X] years of experience in the industry, {} has built a reputation for manufacturing high-quality CNC machinery and providing exceptional customer service. In an effort to further improve their operations and better serve their customers, {} has recently launched CNC Online Order, a new digital platform that allows customers to place orders for CNC machinery and parts directly through their website.“We understand the importance of providing our customers with a seamless and convenient ordering process,” said [Spokesperson’s Name], Vice President of Sales at {}. “With CNC Online Order, our customers can now easily browse our product catalog, select the items they need, and place their orders with just a few clicks. This new platform is designed to enhance the overall ordering experience and make it easier for our customers to do business with us.”The CNC Online Order platform offers a user-friendly interface that allows customers to quickly search for specific products, view detailed product information, and place their orders with ease. Customers can also access real-time inventory availability and pricing information, ensuring that they have the most up-to-date information when making their purchasing decisions.One of the key benefits of CNC Online Order is its ability to streamline the ordering process and reduce the time it takes for customers to receive their orders. By eliminating the need for manual order entry and processing, {} can now fulfill orders more efficiently and expedite the delivery of products to their customers.Additionally, CNC Online Order provides customers with greater transparency and visibility into the status of their orders. Through the platform, customers can track the progress of their orders, receive shipment notifications, and access historical order information, giving them greater peace of mind and confidence in their purchasing experience.“We are committed to leveraging technology to improve every aspect of our business,” said [Spokesperson’s Name]. “CNC Online Order is just one example of how we are embracing digital innovation to better serve our customers. Our goal is to continuously enhance the customer experience and provide our customers with the tools and resources they need to succeed in their operations.”The launch of CNC Online Order reflects {}’s dedication to meeting the evolving needs of their customers and adapting to the digital transformation of the industry. By providing a modern and efficient online ordering platform, {} is empowering their customers to make informed purchasing decisions, save time, and streamline their operations.As {} continues to invest in digital initiatives and customer-centric solutions, the company remains focused on delivering superior value and service to their customers. With CNC Online Order, {} is setting a new standard for the ordering experience in the CNC machinery industry, and cementing their position as a leader in innovation and customer satisfaction.As the digital transformation of the manufacturing industry continues to accelerate, companies like {} are at the forefront of driving change and shaping the future of the industry. With CNC Online Order, {} is demonstrating their commitment to excellence and their dedication to providing customers with the best possible experience when purchasing CNC machinery and parts.To learn more about CNC Online Order and explore the wide range of CNC machinery and parts offered by {}, visit their website at [website URL].

CNC Lathe Machine Parts: Essential Components for Efficient Precision Machining

Title: Revolutionizing Precision Manufacturing with Advanced CNC Lathe Machine PartsIntroduction:In today's rapidly evolving manufacturing industry, technological advancements play a crucial role in enhancing efficiency and precision. One such revolutionizing development is the integration of innovative CNC lathe machine parts. With their state-of-the-art attributes and cutting-edge functionality, these components are revolutionizing precision manufacturing processes across various sectors.Company Overview:As a leading provider of CNC lathe machine parts, our company has established itself as an industry pioneer, continuously pushing the boundaries of innovation. We strive to deliver exceptional precision engineering solutions that cater to the diverse needs of our esteemed clientele. With a commitment to quality, reliability, and staying ahead of the curve, our products have garnered immense recognition and trust in the market.Body:1. Introduction to CNC Lathe Machine Parts:CNC (Computer Numerical Control) lathe machine parts have transformed traditional machining practices by offering unparalleled precision, efficiency, and flexibility. These parts are designed to fit into computer-controlled lathes, which enables automated and highly accurate machining operations. By utilizing advanced software and cutting-edge technology, CNC lathe machine parts have become indispensable tools in industries such as automotive, aerospace, electronics, and medical equipment manufacturing.2. Key Features and Benefits:a) Enhanced Precision: CNC lathe machine parts are equipped with advanced sensors and control systems, which ensure unprecedented accuracy, consistency, and repeatability. This level of precision results in superior product quality and reduced waste, making them ideal for intricate and critical components.b) Simplified Operations: With integrated computerized controls, CNC lathe machine parts provide user-friendly interfaces that require minimal manual intervention. The ability to automate complex machining processes significantly reduces human error, labor costs, and production time.c) Versatility and Flexibility: These components offer extensive customization options, allowing manufacturers to adapt their machining operations to a diverse range of materials, geometries, and specifications. This flexibility enables companies to fulfill customer demands efficiently, even for small production runs.d) Increased Efficiency: Through efficient cutting strategies and optimized tool paths, CNC lathe machine parts significantly improve productivity by reducing cycle times and maximizing machine utilization. This increased efficiency enables manufacturers to meet demanding deadlines and scale production seamlessly.e) Cost-Effectiveness: Although CNC lathe machine parts have a higher initial investment, their long-term cost-effectiveness cannot be overlooked. Their precision and efficiency lead to substantial material and time savings, reducing overall production costs and boosting profitability in the long run.3. Range of CNC Lathe Machine Parts:Our company offers an extensive range of CNC lathe machine parts that cater to various industry requirements. These parts include but are not limited to:a) Spindles and Chuck Systems: These critical components are responsible for holding and rotating the workpiece during machining operations. Our advanced spindles and chuck systems ensure stable and accurate positioning, contributing to the overall precision and quality of the finished products.b) Tool Holders and Accessories: Our tool holders are designed to securely hold cutting tools and optimize their performance. With excellent vibration dampening properties and quick-change systems, these accessories enhance machining stability and reduce tool changeover times.c) Control Systems and Software: We provide cutting-edge control systems and software that integrate seamlessly with CNC lathe machines. These systems offer an intuitive user interface, intelligent tool management, and advanced programming capabilities, enabling manufacturers to achieve precise and efficient machining.d) Cutting Tools: Our comprehensive range of cutting tools includes inserts, drills, and milling cutters designed for various materials and machining requirements. These high-performance tools ensure exceptional machining accuracy and prolong tool life, further optimizing production processes.4. Customer Success Stories: Highlighting success stories of our customers who have benefited from incorporating CNC lathe machine parts in their operations will depict the significant impact these components have had on their businesses. Case studies demonstrating increased productivity, improved quality, and higher cost-efficiency will add credibility to the news content.Conclusion:The integration of advanced CNC lathe machine parts has marked a significant paradigm shift in precision manufacturing. With their unrivaled precision, user-friendly interfaces, and versatility, these components are empowering manufacturers across industries to enhance their competitiveness and achieve outstanding results. As a leading provider of CNC lathe machine parts, our company continues to drive innovation and deliver exceptional solutions that redefine precision machining standards.

Custom Machining Services for CNC Parts: What You Need to Know

CNC Custom Machining is a leading manufacturing company that specializes in precision machining and custom parts production. With state-of-the-art CNC equipment and a skilled team of professionals, the company has built a reputation for delivering high-quality products to a wide range of industries including aerospace, automotive, medical, and more.Founded in 2005, CNC Custom Machining has grown from a small machine shop to a full-service manufacturing facility, boasting a large and diverse customer base. The company's commitment to quality and innovation has made it a trusted partner for businesses looking for reliable and cost-effective machining solutions.The company's manufacturing capabilities include CNC milling, turning, grinding, and EDM services, allowing them to produce complex components with tight tolerances. With a focus on continuous improvement, CNC Custom Machining regularly invests in the latest technology and training to ensure that they can meet the evolving needs of their customers.In addition to their machining services, CNC Custom Machining also provides engineering and design support, helping their clients optimize their product designs for manufacturability and cost-effectiveness. This end-to-end service has made them a valuable resource for companies looking to bring their ideas to market.One of the key differentiators of CNC Custom Machining is their commitment to quality. The company is ISO 9001 certified, ensuring that their manufacturing processes meet the highest standards for consistency and accuracy. They also have a robust quality control system in place, conducting thorough inspections at every stage of production to guarantee that their products meet or exceed customer specifications.CNC Custom Machining has also made significant investments in automation and digitalization, allowing them to streamline their production processes and reduce lead times. This focus on efficiency has enabled the company to offer competitive pricing without compromising on quality, making them an attractive partner for businesses of all sizes.The company's dedication to customer satisfaction is evident in their collaborative approach to project management. They work closely with their clients to understand their unique requirements and provide tailored solutions that meet their specific needs. This personalized service has earned CNC Custom Machining a reputation for reliability and responsiveness in the industry.Looking to the future, CNC Custom Machining is poised for continued growth and success. With a strong foundation built on technical expertise and a commitment to excellence, the company is well-positioned to capitalize on the increasing demand for precision machining services. They are also exploring opportunities to expand into new markets and industries, leveraging their capabilities to offer even more value to their customers.In conclusion, CNC Custom Machining is a leading player in the manufacturing industry, known for their advanced capabilities, superior quality, and exceptional customer service. With a track record of success and a dedication to continuous improvement, the company is well-equipped to meet the needs of a diverse and evolving market, making them a reliable partner for businesses looking for custom machining solutions.

Get Superior Custom Cut Gears for Precision Mechanical Applications

Custom Cut Gears Launches New Line of High-Quality Gears for Industrial Applications[City, State] – [Date] – Custom Cut Gears, a leading manufacturer of precision gears, announced today the launch of their latest line of high-quality gears designed for industrial applications. With their commitment to excellence and state-of-the-art manufacturing processes, Custom Cut Gears aims to provide top-notch solutions to meet the specific needs of various industries.With over 20 years of experience in the industry, Custom Cut Gears has built a reputation for delivering gears of the highest quality that meet or exceed customer requirements. Their team of skilled engineers and technicians specialize in producing gears with exceptional precision, durability, and performance. This new line of gears further solidifies their position as an industry leader.The newly launched line of gears caters to a wide range of industrial applications, including automotive, aerospace, robotics, marine, and more. Custom Cut Gears offers a diverse selection of gear types, such as spur gears, helical gears, bevel gears, worm gears, and planetary gears, among others. This extensive range ensures that customers can find the perfect gear solution for their specific application.What sets Custom Cut Gears apart is their commitment to customization. They understand that each industry has unique requirements, and thus offer customization options to tailor gears to the precise needs of their customers. From material selection to tooth profile modifications, customers can work with Custom Cut Gears to optimize the gears' performance for their specific applications. This level of flexibility ensures that customers receive gears that not only meet their requirements but also enhance their overall efficiency and productivity.Furthermore, all gears manufactured by Custom Cut Gears undergo rigorous quality control processes to ensure the highest level of accuracy and reliability. Their state-of-the-art facility is equipped with advanced machinery and inspection systems, enabling them to maintain tight tolerances and consistent quality across every gear produced. Custom Cut Gears adheres to strict industry standards and certifications, demonstrating their commitment to delivering products of the utmost integrity."We are thrilled to introduce our new line of high-quality gears for industrial applications," said [Spokesperson's Name], spokesperson for Custom Cut Gears. "Our team has put in tremendous effort to develop gears that not only meet industry standards but also exceed customer expectations. With our focus on customization, we aim to provide gears that empower our customers to achieve optimal performance in their respective applications."Custom Cut Gears has collaborated with numerous customers across various industries and successfully helped them solve complex gear-related challenges. Their team of experts works closely with clients to understand their unique requirements and develop gear solutions that deliver exceptional results. The combination of expertise, customization options, and dedication to quality makes them the preferred choice for many companies worldwide.As Custom Cut Gears continues to grow, they remain committed to investing in research and development to stay ahead of industry trends. They are constantly exploring new technologies and techniques to improve their manufacturing processes and design capabilities. This commitment ensures that their customers receive innovative and reliable gear solutions that align with the rapidly evolving industrial landscape.About Custom Cut Gears: Custom Cut Gears is a leading manufacturer of precision gears, specializing in the production of high-quality gears for various industrial applications. With over 20 years of experience, their skilled team of engineers and technicians deliver customized gear solutions that meet the specific needs of their diverse clientele. Custom Cut Gears' commitment to excellence, customization, and quality sets them apart as a trusted gear manufacturer in the industry.For more information about Custom Cut Gears and their range of products, please visit [website] or contact [contact information].

Quality Machined Parts from China: Find the Best Suppliers

Machined Parts China, a leading manufacturer of precision machined parts, is making waves in the manufacturing industry with their high-quality products and reliable services. The company has established itself as a trusted partner for businesses in need of precision components for a wide range of industries, including automotive, aerospace, medical, and more.With a focus on delivering excellence in every aspect of their operations, Machined Parts China has earned a reputation for delivering superior products that meet the highest industry standards. The company's state-of-the-art facilities are equipped with the latest technology and machinery, allowing them to produce precision machined parts with tight tolerances and complex geometries. This capability enables them to meet the unique and diverse needs of their customers with efficiency and precision.One of the key factors that sets Machined Parts China apart from their competitors is their commitment to quality. The company adheres to strict quality control measures at every stage of the manufacturing process, ensuring that all products meet or exceed customer expectations. From raw material inspection to final product testing, Machined Parts China leaves no stone unturned in their pursuit of excellence. As a result, their customers can have confidence in the reliability and performance of the parts they receive.In addition to their dedication to quality, Machined Parts China places a strong emphasis on customer satisfaction. The company works closely with their clients to understand their specific needs and requirements, offering personalized solutions that are tailored to each individual project. Their team of experienced engineers and technicians is able to provide valuable insights and recommendations to help customers optimize their designs for manufacturability and cost-effectiveness.Furthermore, Machined Parts China is committed to upholding the highest standards of environmental responsibility and sustainability. The company has implemented eco-friendly practices in their operations, such as waste reduction, energy efficiency, and recycling initiatives. By prioritizing environmental stewardship, Machined Parts China not only minimizes their impact on the planet but also demonstrates their dedication to corporate social responsibility.As part of their ongoing efforts to serve their customers better, Machined Parts China continues to invest in research and development to stay at the forefront of technological advancements in the industry. By staying abreast of the latest innovations and best practices, the company is able to offer cutting-edge solutions that meet the evolving needs of their customers.In conclusion, Machined Parts China has solidified its position as a trusted and reliable source for precision machined parts. With a steadfast commitment to quality, customer satisfaction, and sustainability, the company has earned the trust and respect of businesses across various industries. As they continue to push the boundaries of excellence, Machined Parts China is poised to remain a leader in the manufacturing industry for years to come.

High-Quality CNC Router for Stainless Steel Cutting: What You Need to Know

The company is a leading manufacturer of CNC routers and other metal cutting and engraving equipment. With a strong focus on innovation and quality, the company has built a reputation for delivering high-performance machines that meet the needs of a wide range of industries, including aerospace, automotive, and manufacturing.One of the company's latest innovations is the CNC Router Stainless Steel, a cutting-edge machine that is specifically designed for working with stainless steel materials. The CNC Router Stainless Steel is engineered to deliver precision and efficiency in cutting and engraving stainless steel, offering a cost-effective solution for businesses looking to enhance their metal fabrication capabilities.The CNC Router Stainless Steel is equipped with advanced features that allow for high-speed and high-precision cutting of stainless steel, including a powerful spindle motor, a robust frame and gantry system, and a state-of-the-art control system. These features enable the machine to deliver superior cutting quality and accuracy, making it ideal for a variety of applications, such as signage, automotive parts, and architectural elements.In addition to its cutting capabilities, the CNC Router Stainless Steel is also equipped with advanced engraving and marking capabilities, allowing users to create intricate designs and patterns on stainless steel materials with unmatched precision. This makes the machine an ideal choice for businesses looking to add custom branding and designs to their stainless steel products.Moreover, the CNC Router Stainless Steel is designed with user-friendly features that make it easy to operate and maintain. The machine is equipped with intuitive software that allows for easy programming and control, as well as a range of safety features that ensure the protection of both the machine and its operators.The CNC Router Stainless Steel is also backed by the company's comprehensive customer support and service, ensuring that businesses have access to expert assistance and technical support whenever they need it. This commitment to customer satisfaction is a cornerstone of the company's business philosophy, and it has helped the company build long-lasting relationships with its clients.The CNC Router Stainless Steel is just one example of the company's commitment to innovation and excellence in the field of CNC cutting and engraving equipment. With a strong focus on research and development, the company continues to push the boundaries of what is possible in metal fabrication, delivering cutting-edge solutions that empower businesses to achieve their production goals.As the demand for stainless steel products continues to grow across a wide range of industries, the CNC Router Stainless Steel represents a game-changing solution for businesses looking to enhance their metal fabrication capabilities. With its advanced features, precision cutting and engraving capabilities, and user-friendly design, the CNC Router Stainless Steel is poised to become an essential tool for businesses seeking to stay ahead of the competition in the metal fabrication industry.In conclusion, the CNC Router Stainless Steel from the company is a testament to the company's commitment to delivering innovative and high-performance CNC cutting and engraving equipment. With its advanced features, precision cutting and engraving capabilities, and user-friendly design, the CNC Router Stainless Steel is set to revolutionize the way businesses work with stainless steel materials. As the company continues to lead the way in the field of metal fabrication equipment, the CNC Router Stainless Steel stands as a testament to the company's dedication to delivering cutting-edge solutions that empower businesses to achieve their production goals.