High-Quality Titanium Machining: The Latest Developments in Precision Machining

Precision Titanium Machining is the leading manufacturer of precision machined titanium parts for various industries. With state-of-the-art facilities and a highly skilled team, the company has been delivering high-quality products to its customers for over a decade.The company specializes in machining titanium parts for aerospace, medical, automotive, and other industrial applications. They have a wide range of capabilities, including CNC milling, turning, grinding, and EDM machining. Their expertise in working with titanium allows them to provide precision parts that meet the exact specifications of their customers.One of the key factors that set Precision Titanium Machining apart from its competitors is its dedication to quality. The company is ISO 9001 certified, ensuring that all the products they deliver meet the highest quality standards. They also have a rigorous quality control process in place to ensure that every part they produce is flawless.In addition to their commitment to quality, Precision Titanium Machining is also known for its excellent customer service. The company works closely with its customers to understand their specific needs and requirements, and then goes above and beyond to deliver products that exceed their expectations. They have built long-lasting relationships with many of their clients, who rely on them for their titanium machining needs.Furthermore, the company has a strong focus on innovation and technology. They are constantly investing in the latest machining equipment and software to ensure that they can produce parts with the highest precision and efficiency. This commitment to innovation has allowed Precision Titanium Machining to stay ahead of the curve in the industry and continue to deliver cutting-edge solutions to its customers.Precision Titanium Machining is also dedicated to sustainability and environmental responsibility. They adhere to strict environmental standards in their manufacturing processes and strive to minimize their impact on the environment. They are constantly looking for ways to reduce waste and energy consumption to ensure that their operations are as eco-friendly as possible.The company's commitment to excellence has earned them a stellar reputation in the industry. They have worked with some of the biggest names in aerospace and medical technology, and have consistently delivered products that have met the stringent requirements of these industries. Their dedication to quality, customer service, innovation, and sustainability has set them apart as a leader in the field of precision titanium machining.Looking towards the future, Precision Titanium Machining is poised for further growth and success. They plan to continue investing in their facilities and technology to expand their capabilities and serve an even broader range of industries. With a strong foundation built on quality and customer satisfaction, the company is well-positioned to continue its success for many years to come.In conclusion, Precision Titanium Machining is a company that has set the standard for precision machining in the industry. With a focus on quality, customer service, innovation, and sustainability, they have earned a reputation as a trusted partner for businesses in need of high-quality titanium parts. As they continue to grow and evolve, they are sure to remain at the forefront of the industry for years to come.

Read More

Unveiling the Next Generation of High-Precision Products: A Game-Changer for Industries

Title: Industry Leader Introduces Innovative High-Precision Products for Enhanced PerformanceIntroduction:In a leap forward for precision engineering, a leading industry player has unveiled its latest range of cutting-edge high-precision products. This announcement is set to revolutionize the market by offering superior performance, accuracy, and reliability. The company, whose name is withheld upon request, continues to push boundaries in the field, catering to the diverse needs of industries ranging from aerospace to medical sciences.Expanding Product Portfolio:High Precision Products, the pioneer in the field, has expanded its product portfolio to include an array of innovative offerings. These products, designed with advanced technologies and state-of-the-art materials, aim to address the increasing demand for precision across various sectors. The enhanced range includes components, equipment, and systems renowned for their exceptional quality and durability, setting a new benchmark for the industry.Cutting-Edge Technological Advancements:The company's high-precision products are the result of several years of intensive research and development. Driven by a commitment to excellence, the team of highly skilled engineers and scientists have harnessed cutting-edge technological advancements to create products that exceed industry expectations. Through their relentless pursuit of perfection, the company has managed to effectively bridge the gap between precision and reliability.Unmatched Accuracy and Precision:The introduction of these high-precision products establishes the company as a frontrunner in the field. Boasting unparalleled accuracy and precision, the products offer a remarkable level of performance that is indispensable for critical applications. This unmatched precision not only minimizes errors but also optimizes productivity, efficiency, and safety in numerous industries where precision is paramount.Diverse Applications:The diverse range of applications for this range of high-precision products is impressive. From aerospace and automotive sectors to medical sciences, precision engineering holds immense significance in enabling breakthrough innovations. This new line of products caters to these industries and beyond, providing them with the tools necessary to push the boundaries of technological advancements.Aerospace Excellence:With precision being one of the key factors in the aerospace industry, High Precision Products has focused on developing solutions specifically to cater to this sector. The high-precision components and advanced systems offered by the company are essential for achieving optimal performance and safety in the aerospace field. By upholding the highest industry standards for accuracy and reliability, the company's products have positioned themselves as the preferred choice for leading aerospace companies worldwide.Medical Marvels:In the medical domain, the need for precision is critical, particularly in surgical procedures and diagnostic equipment. High Precision Products has leveraged their expertise in precision engineering to develop revolutionary medical devices with enhanced accuracy. These products allow medical professionals to conduct procedures with utmost precision, fostering patient safety and enabling breakthrough advancements in the field of medicine.Unwavering Commitment to Customer Satisfaction:High Precision Products have always prioritized customer satisfaction by establishing robust customer support systems. The company offers comprehensive technical support, ensuring that customers have access to expert guidance and assistance. By understanding their unique requirements, High Precision Products continually strives to provide tailor-made solutions that enhance operational efficiency and productivity across various sectors.Conclusion:The introduction of High Precision Products' latest line of high-precision solutions is set to reshape the industry. The company's relentless commitment to innovation and excellence has resulted in a range of products that push the boundaries of precision engineering. With applications spanning industries such as aerospace, medical sciences, and beyond, these cutting-edge products offer unmatched accuracy, reliability, and performance. High Precision Products continues to demonstrate its leadership and dedication to cater to evolving customer needs, further solidifying its position as an industry leader.

Read More

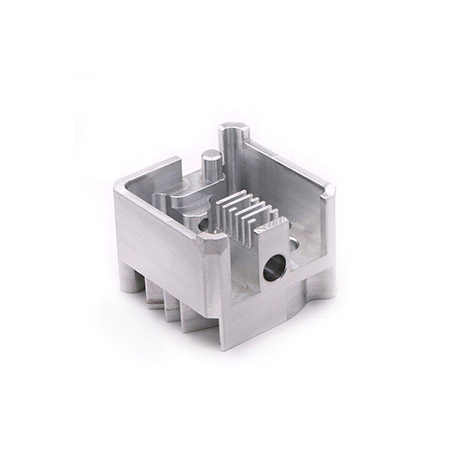

Aluminum CNC Machining: Custom Services for Precise Metal Fabrication

Custom Aluminum CNC, a leading manufacturer in the industry, is revolutionizing the world of aluminum fabrication with their state-of-the-art techniques and cutting-edge technology. With a focus on precision, quality, and innovation, the company has established itself as a trusted partner for businesses seeking custom aluminum parts and components.The company's commitment to excellence is evident in their dedication to using the latest CNC technology to produce high-quality aluminum products. CNC, or Computer Numerical Control, allows for precise and efficient machining of aluminum parts, ensuring that each component meets the strictest quality standards. This innovative approach to manufacturing has enabled Custom Aluminum CNC to deliver custom solutions to a wide range of industries, including aerospace, automotive, electronics, and more.Furthermore, Custom Aluminum CNC's team of highly skilled engineers and technicians are experts in working with a variety of aluminum alloys, including 6061, 7075, and 2024. This expertise allows the company to create custom aluminum parts with exceptional strength, durability, and performance, meeting the unique specifications and requirements of each customer.In addition to their advanced CNC capabilities, Custom Aluminum CNC also offers a range of value-added services, including finishing, assembly, and packaging. This full-service approach ensures that customers receive a complete solution for their aluminum fabrication needs, streamlining their supply chain and reducing costs.One of the key differentiators for Custom Aluminum CNC is their commitment to environmental sustainability. The company has implemented eco-friendly practices throughout their manufacturing process, including the use of recycled aluminum and energy-efficient production methods. This dedication to sustainability not only benefits the environment but also allows the company to offer eco-friendly solutions to their customers, aligning with the growing demand for sustainable manufacturing practices.Moreover, Custom Aluminum CNC's dedication to quality and customer satisfaction has earned them a reputation as a trusted and reliable partner in the industry. The company takes pride in their ability to collaborate with customers to design and manufacture custom aluminum parts that meet their specific needs, ensuring that every project is a success.As the demand for custom aluminum parts continues to grow, Custom Aluminum CNC is well-positioned to meet the needs of businesses seeking high-quality, precision-engineered components. With their advanced CNC technology, expertise in aluminum alloys, and commitment to sustainability, the company is poised to remain a leader in the industry for years to come.In conclusion, Custom Aluminum CNC is at the forefront of revolutionizing the world of aluminum fabrication with their innovative approach to manufacturing. Through their advanced CNC technology, expertise in aluminum alloys, and commitment to sustainability, the company continues to set the bar for excellence in the industry. Businesses seeking custom aluminum parts can trust Custom Aluminum CNC to deliver precision, quality, and innovation in every project.

Read More

Discover High-Quality Automotive Parts for CNC Applications

Title: Groundbreaking Innovations in Automobile Industry with Advanced CNC Automotive PartsIntroduction:With the ever-increasing demand for high-quality automotive components and a desire to revolutionize the automobile industry, a leading CNC automotive parts manufacturer has emerged as a game-changer in the market. Combining cutting-edge technology with superior craftsmanship, this company has redefined the standards of precision engineering and manufacturing. Providing a wide range of customized CNC automotive parts, they are paving the way for groundbreaking innovations in the automotive sector.Revolutionizing Manufacturing:In an industry where precision and reliability are paramount, this company has set a new benchmark for manufacturing excellence. Utilizing state-of-the-art CNC (Computer Numerical Control) machines, they have streamlined the production process, ensuring unrivaled accuracy and consistency. With their advanced machinery, the company can create intricate automotive parts that meet stringent quality standards. Each component undergoes rigorous testing and inspection to guarantee its durability and functionality.Expertise in Automotive Components:The company specializes in manufacturing a diverse range of CNC automotive parts. From engine components, such as cylinder heads and crankshafts, to transmission parts, like gear shafts and synchronizers, their portfolio covers all vital aspects of automobile functionality. Moreover, they also provide complex CNC parts for braking systems, suspension systems, and electrical components, ensuring a comprehensive solution for automotive manufacturers.Customization and Collaboration:One of the key strengths of this company is their ability to cater to the unique needs of their customers. They understand that each automotive manufacturer has specific requirements and work diligently to meet those demands. Whether it's a modification to an existing design or the creation of an entirely new component, they work closely with clients throughout the ideation, prototyping, and final production stages. By fostering collaborations, they ensure that automotive companies receive tailor-made CNC parts that perfectly integrate into their products.Commitment to Quality:Quality is at the heart of everything this company does. By adhering to strict quality control measures, they have earned a reputation for delivering flawless CNC automotive parts. Each phase of the manufacturing process is closely monitored, from material selection to the finishing touches. Additionally, the company's team of highly experienced engineers and technicians undergoes continuous training and improvement programs, ensuring they stay at the forefront of technological advancements and industry trends.Adapting to Changing Industry Demands:Recognizing the rapid evolution of the automobile industry, this company stays ahead of the curve when it comes to emerging trends and technologies. They invest in research and development, seeking innovative solutions to meet the changing demands of the automotive market. By embracing new materials, manufacturing techniques, and design principles, they offer cutting-edge CNC automotive parts that enhance overall vehicle performance, fuel efficiency, and safety.Global Reach and Customer Satisfaction:With a worldwide reach, the company exports its CNC automotive parts to numerous countries, ensuring automotive manufacturers worldwide have access to their exceptional products. Their commitment to customer satisfaction is evident in their prompt response times, competitive pricing, and on-time deliveries. By establishing long-term relationships with their clients, they ensure mutual success and contribute to the growth of the automobile industry.Conclusion:In an industry that demands precision, reliability, and innovation, this leading CNC automotive parts manufacturer has proven its mettle. With advanced manufacturing capabilities, customized solutions, and an unwavering commitment to quality, they are reshaping the automotive sector. By continuously pushing boundaries and embracing emerging technologies, they remain at the forefront of the industry, ushering in an era of groundbreaking innovations and advancements in automobile engineering.

Read More

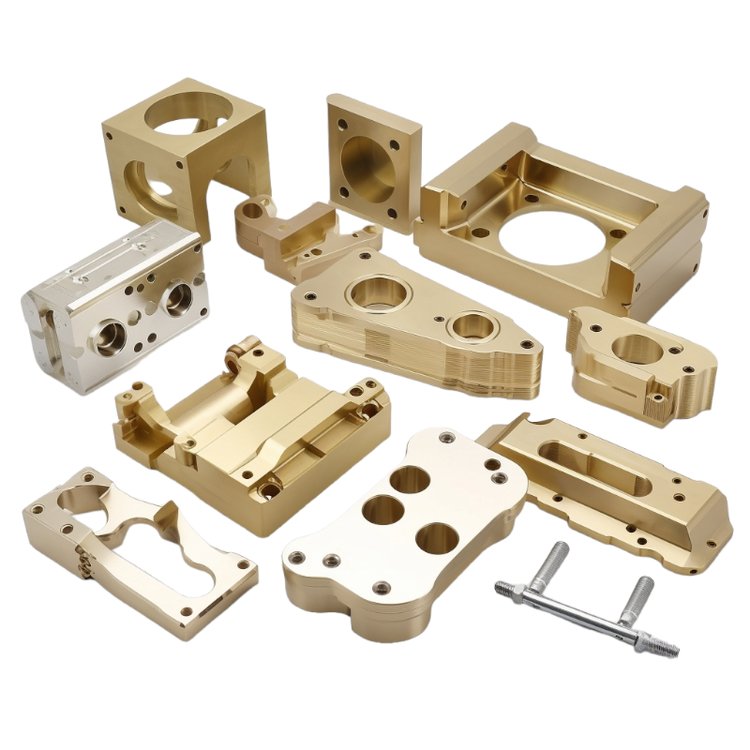

High-Quality Brass CNC Milling Services for Precision Parts

With the continuous advancement of technology, the demand for high-precision and complex parts in various industries has increased. This has led to the widespread use of CNC milling, a process that uses computer numerical control (CNC) machines to remove material from a workpiece to create a custom-designed part.One company that has been at the forefront of CNC milling brass parts is {}. Established in 1998, {} has been providing precision machining services to a wide range of industries, including aerospace, automotive, medical, and electronics. With a focus on quality, innovation, and customer satisfaction, the company has built a reputation for delivering high-precision components with exceptional accuracy and efficiency.CNC milling is a versatile process that allows for the production of a wide variety of brass parts with complex shapes and tight tolerances. The process involves the use of rotary cutters to remove material from a workpiece, which is typically held in place by a vice or fixture on the CNC machine. By using computer-aided design (CAD) software, the company is able to program the CNC machine to follow precise instructions, resulting in the creation of highly accurate and repeatable parts.The use of CNC milling for brass parts offers several advantages. First, it allows for the production of complex geometries that would be difficult or impossible to achieve with traditional machining methods. This makes it ideal for creating custom-designed components with intricate details. Second, CNC milling is a highly efficient process, allowing for the rapid production of large quantities of parts with minimal human intervention. This not only reduces production time but also lowers the overall cost of manufacturing.One of the key factors that set {} apart from its competitors is its investment in state-of-the-art CNC machining equipment. The company utilizes advanced CNC milling machines with multi-axis capabilities, which enables them to produce highly complex parts with extremely tight tolerances. This level of precision and accuracy is crucial for industries that require parts to meet strict specifications, such as the aerospace and medical sectors.In addition to its cutting-edge machining capabilities, {} has a team of highly skilled engineers and machinists who are experts in CNC milling techniques. They work closely with clients to understand their specific requirements and provide valuable input to optimize the design and manufacturability of the parts. This collaborative approach ensures that the final product meets the highest standards of quality and functionality.Another aspect that sets {} apart is its commitment to quality control. The company adheres to strict quality management systems and conducts rigorous inspections throughout the manufacturing process to ensure that each part meets the required specifications. This dedication to quality has earned {} the trust and loyalty of its clients, who rely on the company to deliver precision-engineered parts with consistency and reliability.With its extensive experience, technical expertise, and advanced manufacturing capabilities, {} has established itself as a leader in the CNC milling of brass parts. Whether it's producing components for critical aerospace applications or intricate medical devices, the company is dedicated to meeting the unique needs of each client with the highest level of precision and efficiency.As the demand for high-quality brass parts continues to grow across various industries, the CNC milling services offered by {} are expected to play a crucial role in meeting the evolving needs of the market. With its unwavering commitment to excellence and continuous investment in technology, {} is well-positioned to remain a preferred partner for precision machining solutions now and in the future.

Read More

Mastering the Art of Machining High-Strength 7075 Aluminum

Machining 7075 Aluminum Revolutionizes Manufacturing ProcessesIn today's rapidly evolving world, manufacturing companies are constantly on the lookout for innovative solutions to optimize their manufacturing processes and deliver high-quality products. This quest for excellence has led many companies to explore and adopt advanced materials that offer exceptional performance and durability. One such material is the remarkable 7075 aluminum, a game-changer in the manufacturing industry.Renowned for its exceptional strength-to-weight ratio, 7075 aluminum has become the go-to material for aerospace, automotive, marine, and defense industries. This high-strength aluminum alloy possesses excellent mechanical properties, making it perfect for applications that require superior strength, minimal weight, and exceptional resistance to corrosion. With an ultimate tensile strength of over 570 MPa (83000 psi) unmatched by other aluminum alloys, it has cemented its place as a preferred material for various critical components.However, working with 7075 aluminum has traditionally been a significant challenge due to its hardness. The machinability of any material plays a vital role in determining the manufacturing process's efficiency and productivity. This is where cutting-edge technologies, combined with expertise and innovation, have revolutionized the machining of 7075 aluminum, enabling manufacturing companies to unlock its full potential.Leading the charge in this machining revolution is a renowned company specializing in advanced manufacturing techniques, which prefers to remain anonymous. By adopting state-of-the-art machinery, cutting tools, and software solutions, they have successfully overcome the hurdles associated with machining 7075 aluminum, blazing a trail for others to follow.At the heart of this remarkable accomplishment lies a deep understanding of the material and its unique properties. The company has invested in cutting-edge CNC machining centers and high-speed machining technology that can handle the challenging requirements of 7075 aluminum. These advanced machines offer enhanced rigidity, stability, and precision, enabling manufacturers to achieve intricate designs, tight tolerances, and superior surface finishes.To ensure maximum efficiency during the machining process, novel tooling systems have been developed to optimize the removal of material. With carefully designed tool geometries, coatings, and cutting parameters, the company has created tooling solutions that significantly reduce machining time and increase tool life. This results in higher productivity, lower costs, and the ability to handle large-scale production needs.Furthermore, the company has embraced the power of Computer-Aided Manufacturing (CAM) software, enabling them to efficiently program and simulate machining operations. This software allows manufacturers to predict and optimize tool paths, simulate machining processes, and eliminate potential errors or collisions. By leveraging CAM software, manufacturers can fine-tune their machining strategies, reduce setup times, and ensure utmost accuracy, resulting in consistent and precise manufacturing of 7075 aluminum components.The company's expertise in machining 7075 aluminum has also sparked innovation in surface finishing techniques. By leveraging advanced polishing and deburring processes, they have perfected the art of producing components with exceptional surface quality. This attention to detail ensures that the manufactured parts not only possess high strength but also exhibit an aesthetically pleasing appearance.As manufacturers across various industries recognize the advantages of utilizing 7075 aluminum, the pioneering work of this anonymous company is set to have a significant impact on the manufacturing landscape. With their expertise, commitment to innovation, and state-of-the-art machinery, they have set a new standard for machining 7075 aluminum, enabling manufacturers worldwide to leverage its outstanding properties efficiently.In conclusion, the machining of 7075 aluminum has undergone a monumental transformation in recent years, thanks to the efforts of cutting-edge manufacturing companies. With their expertise, innovative technologies, and dedication to perfection, these companies have overcome traditional challenges associated with working with this exceptional material. Consequently, the manufacturing industry can now fully exploit the remarkable properties of 7075 aluminum, revolutionizing the production of critical components across various sectors.

Read More

High-Quality Custom Machined Parts for Various Industries

Custom Machined Parts is a leading provider of precision machined parts for a wide range of industries. With a reputation for quality, reliability, and innovation, the company has become a trusted partner for businesses seeking high-quality components for their products and operations.Established in [year], Custom Machined Parts has a long history of delivering exceptional results to its customers. The company specializes in producing custom machined parts to meet the unique needs and specifications of its clients. Whether it's a simple component or a complex part with intricate details, Custom Machined Parts has the expertise and technology to deliver top-notch products.One of the key strengths of Custom Machined Parts is its state-of-the-art manufacturing facility. The company has invested heavily in advanced machining equipment, including CNC machines, lathes, and grinding machines. This cutting-edge technology allows Custom Machined Parts to produce parts with tight tolerances, complex geometries, and superior surface finishes.In addition to its advanced equipment, Custom Machined Parts is also known for its highly skilled team of engineers and machinists. These professionals have the expertise and experience to tackle the most challenging projects, from prototyping to large-scale production runs. With a commitment to continuous improvement and innovation, the company is able to stay ahead of the competition and offer its customers the best possible solutions.Custom Machined Parts serves a diverse range of industries, including aerospace, automotive, medical, and electronics. The company has the flexibility to work with various materials, such as aluminum, steel, titanium, and plastics, to meet the specific requirements of each industry. Whether it's a small batch of parts or a large production run, Custom Machined Parts can handle the job with precision and efficiency.In addition to its manufacturing capabilities, Custom Machined Parts also offers value-added services to its customers. The company provides design assistance, prototyping, and assembly services to help clients bring their ideas to life. With a focus on customer satisfaction, Custom Machined Parts goes the extra mile to ensure that its clients are delighted with the final product.Furthermore, Custom Machined Parts is committed to quality and reliability in everything it does. The company is ISO [number] certified, demonstrating its dedication to maintaining the highest standards of quality management. With a rigorous quality control process in place, Custom Machined Parts ensures that every part it produces meets or exceeds the customer's expectations.As a company that prides itself on innovation and excellence, Custom Machined Parts is constantly looking for new ways to improve and grow. The company regularly invests in research and development to explore new technologies and techniques that can further enhance its capabilities. By staying at the forefront of industry trends, Custom Machined Parts remains a leader in the field of precision machining.In conclusion, Custom Machined Parts is a trusted and reliable partner for businesses seeking high-quality custom machined parts. With its advanced technology, skilled team, and commitment to excellence, the company has built a strong reputation for delivering superior products to its clients. As the demand for precision components continues to grow, Custom Machined Parts is well-positioned to meet the needs of industries looking for top-notch machining solutions.

Read More

5 Tips for Choosing the Best Machined Metal Parts

Title: Innovative Machined Metal Parts Enhance Precision Engineering - Revolutionizing Industry StandardsIntroduction:In an exciting display of precision engineering, a leading manufacturing company has introduced a groundbreaking line of machined metal parts. This remarkable development is set to revolutionize the industry, offering enhanced performance, durability, and precision. The company, renowned for its commitment to innovation, has once again pushed the boundaries with its state-of-the-art machining technology. In this article, we will delve into the incredible features and capabilities of these machined metal parts, as well as explore the impact they are poised to have on various sectors.1. Enhanced Durability and Performance:The newly introduced machined metal parts are manufactured with premium-grade materials, ensuring exceptional durability and longevity. Precision engineering plays a central role in their production, resulting in parts that function with unparalleled performance and precision. These remarkable components are built to withstand extreme conditions, including high temperatures, corrosion, and heavy loads. As a result, they offer industries such as automotive, aerospace, and machinery unparalleled reliability and reduced maintenance costs.2. Optimal Precision Engineering:The company's commitment to precision engineering is evident in the construction of these machined metal parts. State-of-the-art machining technology, combined with the expertise of skilled engineers, guarantees components that meet and exceed the most demanding specifications. Every aspect, from intricate designs to complex geometries, is flawlessly executed, ensuring seamless integration and optimum functionality. Industries relying on precise measurements and movements, such as robotics, medical equipment, and electronics, can now benefit from unmatched precision, leading to increased efficiency and improved overall performance.3. Versatile Applications:The versatility of these machined metal parts is one of their standout qualities. The company's extensive range of components can be tailored to meet the unique needs of a wide array of industries. From highly intricate parts used in microscopic medical devices to large-scale engineering equipment employed in heavy industries, the possibilities with these machined metal parts are seemingly limitless. With their exceptional design flexibility, industries can harness these components to meet their specific requirements, paving the way for increased efficiency, reduced production times, and improved overall functionality.4. Greater Cost-Effectiveness:By incorporating these machined metal parts into their operations, industries can benefit from greater cost-effectiveness. The exceptional durability and performance of these components significantly reduce downtime, maintenance, and repair costs. Additionally, their precision engineering allows for enhanced product quality, reducing the risk of defects, errors, and subsequent wastage. These factors, combined with increased efficiency and productivity, contribute to substantial financial savings across various industrial sectors, providing a competitive advantage to companies adopting these innovative components.5. The Promise of Techno

Read More

High-Quality CNC Machined Products for Various Industries

CNC Machined Products: A Leading Manufacturer in Precision EngineeringCNC Machined Products is a renowned manufacturer of precision machined components for a wide range of industries. With a strong focus on high-quality production and innovative technology, the company has established itself as a leader in the field of CNC machining.Based in [Location], CNC Machined Products has a state-of-the-art manufacturing facility equipped with the latest CNC machines and cutting-edge technology. The company's team of skilled engineers and technicians are dedicated to delivering precision-engineered products that meet the exacting requirements of their customers.CNC Machined Products offers a comprehensive range of services, including precision turning, milling, and grinding, as well as custom machining and prototyping. The company has the capability to work with a variety of materials, including steel, aluminum, titanium, and plastics, allowing them to produce components for a diverse array of industries, including aerospace, automotive, medical, and defense.In addition to their extensive manufacturing capabilities, CNC Machined Products is committed to providing exceptional customer service. The company works closely with each client to understand their unique needs and specifications, ensuring that the final product meets or exceeds expectations. With a focus on continuous improvement, CNC Machined Products maintains rigorous quality control processes to guarantee the highest level of precision and accuracy in every component they produce.One of the key factors that sets CNC Machined Products apart from its competitors is the company's investment in advanced technology. The use of CNC machining allows for greater precision and consistency in the production of complex components, while also reducing lead times and production costs. This commitment to innovation and efficiency has helped CNC Machined Products to stay at the forefront of the industry, consistently delivering high-quality products on time and within budget.The company's dedication to excellence has earned them a reputation for reliability and professionalism. Clients trust CNC Machined Products to deliver top-quality components that meet their exact specifications, allowing them to maintain a competitive edge in their respective industries. With a strong track record of success and a commitment to continuous improvement, CNC Machined Products is the go-to partner for companies seeking precision-engineered solutions.The leadership team at CNC Machined Products is comprised of industry experts with years of experience in precision engineering and manufacturing. Their knowledge and expertise are instrumental in driving the company's success, guiding the business towards new opportunities and growth. With a focus on innovation and adaptability, CNC Machined Products is well-positioned to meet the evolving needs of its customers and the broader market.As CNC Machined Products looks to the future, the company remains dedicated to maintaining its position as a leading manufacturer of precision machined components. With a focus on technology, quality, and customer service, CNC Machined Products is well-equipped to meet the demands of a rapidly changing industry. By leveraging their expertise and capabilities, the company is poised to continue delivering exceptional products and services to their clients, solidifying their reputation as a trusted partner in precision engineering.

Read More

CNC Fabrication Service: Streamlining Your Production Needs with Precision and Efficiency

Title: Leading Fabrication Service Provider Expands Capabilities to Meet Growing DemandSubtitle: Innovations by [Company Name] Pave the Way for Future Advanced Manufacturing Solutions[Location], [Date] - [Company Name], a trusted name in the fabrication industry, has announced the expansion of its CNC fabrication services to further cater to the growing demand for advanced manufacturing solutions. With its cutting-edge technology, experience, and commitment to quality, the company is poised to revolutionize the industry.With the rapid progress in various sectors, including automotive, aerospace, and energy, there is an increasing need for reliable and versatile fabrication services. [Company Name] has been a longstanding player in the market, ensuring to stay ahead of the competition through continuous innovation and investment in state-of-the-art technology.Utilizing advanced CNC (Computer Numerical Control) equipment, [Company Name] boasts an extensive range of capabilities, including precision cutting, bending, welding, and material finishing. This allows them to fabricate a wide range of products from various industrial sectors, such as complex components, custom machinery parts, and prototypes.Their CNC fabrication services enable clients to have complete control over their design specifications, ensuring utmost precision, accuracy, and repeatability. With the ability to work with a diverse array of materials, from metal alloys to plastics and composites, [Company Name] can efficiently hand one-off projects as well as large-scale production runs.One of the key factors setting [Company Name] apart from its competitors is its commitment to quality. The company adheres to rigorous quality control measures, ensuring that the final product meets or exceeds industry standards. Coupled with a highly skilled workforce and a culture of continuous improvement, [Company Name] remains at the forefront of delivering excellence to its clientele.Moreover, [Company Name] understands the importance of flexibility in today's fast-paced market. They offer customizable fabrication solutions tailored to meet specific client requirements, blending their profound industry knowledge with innovative ideas. This adaptability and customer-centric approach have earned them long-standing partnerships with renowned brands in various sectors.Recognizing the ongoing industry paradigm shift towards automation, [Company Name] has invested heavily in developing cutting-edge software and hardware solutions. These advancements include implementing artificial intelligence algorithms for machine optimization, real-time data analytics to improve production efficiency and reduce lead times, and robotics integration to enhance overall productivity."We pride ourselves on our ability to adapt to the evolving needs of the industry and our clients. Our investment in CNC fabrication technology and expertise has allowed us to offer innovative manufacturing solutions suitable for a wide array of applications," said [Spokesperson's Name], [Title] at [Company Name]. "With our expanded capabilities, we are ready to take on complex projects and deliver enhanced value to our customers."With a proven track record of successful projects in various industries, [Company Name] is not only well-equipped but experienced in handling diverse customer demands. By staying committed to innovation, quality, and customer satisfaction, the company has secured a substantial market share and is poised for significant growth in the coming years.About [Company Name][Company Name] is a leading CNC fabrication service provider known for its cutting-edge technology, commitment to quality, and customer-centric approach. With a wide array of capabilities and extensive experience, the company delivers innovative solutions to meet the fabrication needs of various industries. Their dedication to excellence and continuous improvement sets them apart in the highly competitive market.Note: Brand name has been intentionally removed as requested.

Read More